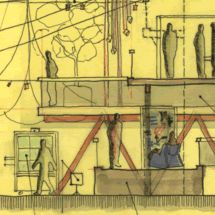

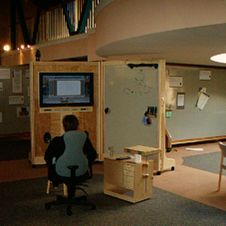

| A core competency of the MG Taylor ValueWeb is the integration of the Design, Build, Use process. This has been the case since our beginning. | | This exercise is done in rapid iterations - it is more than rapid prototyping or lean production - it is lean creation. | | On one hand, we formulate a THERE from which we “get” in all the work we do; on the other, we do not build until we have customers/users in mind - we always develop for specific projects and applications. | | In 1997, we built the Cambridge KnOwhere Store in 30 days over the Christmas and New Year Holidays.This was the complete process design through first use. The project proceeded from a raw open concrete-to-concrete space (that had been a jam factory) to a completely finished envionment. It was the second allpication of our armature concepts and the first where we started the development of manufactured armature components. To date, this has been our most successful buildout of a space in terms of the time, cost, quality, economic return equation. | | Our core thrust is work process • technology • environment integration [link]. | | MG Taylor 1982 Annual Report Cover | | The diagram illustrates our vision of how these processes are integrated into one seamless system of work. This is the THERE [link] we have bringing to every opportunity. | | All of the tools shown in this diagram now exist at reasonable cost except the very large read-write Radiant Walls. It is now possible to make this functionality a part of the everyday work environment. | | In April, this year (1999), I worked with Bill Stumpt [password protected link] to develop some future-focused ideas for Herman Miller [password protected link]. This was a space for the HM senior leadership and their KnowledgeWorker support Team. Customers and clients also have access to this environment. The idea was for the leadership to work here as a team, as well as, each having work environments back in their individual functional areas. | All this called for RemoteCollaboration and RemotePresence [link]. It assumed an intense mobile multimedia capability. | | The unit shown below is an AI WorkWall with embedded computer, video conferencing, multimedia editing and Hypertext web publishing. It is designed to move to where it is required (eliminating the need for a specialized room) and to be wireless except for power. | |  | Design for Herman Miller Workspace - April, 1999 This was the first sketch of the MagicWindow concept. link | | | As I developed this concept on the Herman Miller drawing I called Bill Blackburn of AI and we decided that the time had come to build the unit. We discussed the project during our August DesignSession and again at Glasgow [link]. By that time it was on the MG Taylor “End Game” AndMap as BM - 103. We decided that for a number of strategic reasons we had to make the commitment. | | The Start of a 30 Day Process | | On October 15th. Bill Blackburn put out his specification and the ValueWeb sprang into action. This is when things got truly interesting. Up to this point the idea was a concept - although it was tied to our overall design strategy and IP [link] it now had to be translated in to a specific product with a brand image. | | Bill’s communication went out to Paul Lyons in Mexico, our Glasgow shop and to Eric Gibson and Sean Gosine of Proximal Networks in Boulder, Colorado. Bill’s sketch established the basic configuration. | | By October 22 when the AI team arrived in Palo Alto for a design review of our new products [link], Paul had his concept drawing in hand. In the mean time Eric and Sean were developing solutions to the technical challenges. | | Paul Lyons Concept Drawing - October 1999 | | Pat Gibson took the role of venture capitalist and on November 2nd Paul, Eric and Sean arrived at the Glasgow shop. A rapid prototyping process [link] began which involved establishing final details (for this iteration), electronic options and fabrication processes. The piece was fabricated by Wednesday the 10th and taken to Boulder by Eric and Sean were it was fitted with more electronics. They then drove it to Palo Alto where is arrived mid day on Saturday the 13th. | | Saturday @KnOwhere as the equipment was being installed in MagicWindow. | |  | | The Glasgow of the project was the most critical and the most fun. Many, many judgments involving function, cost, aesthetics, manufacturablity, durability, marketability all had to be made in concert. | | If “planned,” and controlled by an army of managers it takes months and great amounts of money to get through this phase. Instead, a small Team drives an iteration of the work through a complete cycle of the creative process [link]. The necessary skill is to make good engineering tradeoffs and not compromises. In our case, the iteration had to be good enough to demonstrate the functionality were were after and complete enough so that we learned what is necessary to go to production with the next one. | | In the mean time, working virtually with Mike Bernarek, our IP attorney, the Team, Bill, Pat and myself got the Patent filed. | | In the mean time, working virtually with Mike Bernarek, our IP attorney, the Team, Bill, Pat and myself got the Patent filed. | | While the truck was in route with the prototype, Bill Blackburn was showing drawings and pictures to clients and starting the process of getting their individual technology specifications. One of the better features of MagicWindow is that the technology make up can be about anything a user requires. | | The task at Palo Alto is, as I am writing this (November 15, 1999), to get the whole thing put together by the time the KnOwhere Store DesignShop event starts. MagicWindow will be working this event delivering value to the participants. |  | Monday @ KnOwhere 2 hours before start of the knOwhere DesignShop. Our first attempt to embedd technology into our WorkFurniture. | | | | In the early 60s [link], in New York [link], I developed the design/build process that has became known as FasTracking. This is a dangerous process. On one hand, it can produce spectacular results cutting up to 40% of the cost and more than half the time of a project. On the other hand, if it gets away from you, the mess can be unbelievable. | | I perfected the method nearly 10 years later in the swimming pool industry where I had the opportunity to participate in high volume construction over a multi-year period. This is an other story [link]. What was learned, however, is important here: design/build in not enough. Design•Build•Use is necessary and it has to involve an entire ValueWeb [link] to be a stable system [link]. The risks have to be taken together and the rewards have to be shared together. The 4 Step Recreation [link] Model is key to success. It is this awareness and attitude that make rapid iterations work. Without these feedback loops in place, the whole thing can spin out of control. | | Building an organization that can do the lean creation [link] processes is a critical core competency of any 21st Century enterprise. This can only be done well at the level of the enterprise’s ValueWeb - it cannot happen with a sufficient level of complexity inside the “skin” of any business or government - perhaps not even inside any Nation [link]. | | “Supply Chain Management” as it is understood and practiced today is too linear and simple to do more than improve what is already a broken system. It is a start but it will not provide consistent breakthrough. | | The lean creation process is a system [link] of work (supported by an integrated suite [link] of technology tools, work processes and environment) with all the Stackholder interests aligned. It proceeds through a series of time and resource constrained rapid iterations of design, build use - each producing useful products that rapidly lead to even more useful products . | | No matter a product or a service; high volume or custom; simple of sophisticated; this method of making things is impossible to beat. Not only the product is refined - the process, and organization that builds, is improved. Time and costs go down, quality up. The entire ValueWeb profits. Creativity soars and work become fun again. With an eye out for the larger system impacts, sustainability becomes possible. Lean methods require an intelligent mix of technology and craft. Art and technique coexist. The human face of business returns and the competition becomes one between goods not people and organizations. The striving is for excellence not dominance and narrow financial profits alone. This is a different view of work and business than our present reality is made of. This is a vision of work worth working for. | | Matt Taylor

Palo Alto

November 15, 1999

SolutionBox voice of this document:

VISION • STRATEGY • SCHEMATIC | | |

posted: November 15, 1999 revised: July 12, 2003

• 19991115.239762.mt • 19991205.112266.mt •

• 20030712.000890.mt • note: this document is 99% finished Copyright© Matt Taylor 1999, 2003 Matt Taylor 615 525 7053

me@matttaylor.com IP Statement and Policy | |

|