Hexipent

Geodesic Dome cluster - 1979

Night view |

| The

dome offers great promise along with a set of serious

design challenges. One of these is how to bring it

gracefully to the ground [link] -

another, is how to utilize the basic round shape

- which works well for some functions

but not for others - in the creation of buildings

that require multi-functional spaces. |

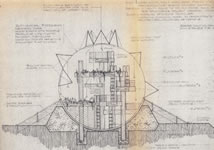

| The

drawing, above, is from a 1979 project exploring

how the Hexipent geodesic dome configuration, developed

by Bucky, could be used for prefabricating modest

scale,

light

weight, movable buildings. The dome is built in hexagon

and pentagon segments that are shop built and assembled

on site; thus, the entire superstructure is made

up of a few easy to handle pieces that can be erected

in

a day or two. A standing seam flashing and counter

flashing system between these segments facilitates

quick waterproofing.

Recently,

a project

in China [link] -

one of much larger scale and higher technology, than

shown here, - used the hexipent configuration

as a basis for prefabricating components. |

| I

call this dome design the “snowflake” configuration.

Usually, a dome of this type (low-tech, employed

as home or small office use) will meet the ground

with a series of half hexagons where doors and windows

are usually placed. This is awkward and ugly - the

forms do not work together any more than carriage

lanterns

would

be

right on

a modern

automobile. This

configuration also fails to provide adequate height

for a comfortable two story layout with domes of

modest

size.

There

are thousands of such low-tech geodesic domes that

fail to meet the promise of open space and who squat

uncomfortably on the Earth and enjoy multiple waterproofing

problems. |

| In

this design, the pentagons sills are 3 feet above

the grade and, in each half-hexagon, a horizontal

hexagon roof segment forms a space off the main dome

area - 5 per dome. This provides small rooms, entry

areas, connection segments to other domes. It allows

a more friendly meeting of the structure to the ground.

In the illustration shown, berms come up to the dome

structure sills. This provide the head height necessary

for the hexagon areas and makes the dome, itself,

high enough for a second level under the higher parts

of the dome. Inside, this provides three foot vertical

walls (below each non-opening hexagon and pentagon)

useful for built-ins and furniture docking. The berm,

on the outside, keeps the profile of the structure

low and bridges between structure and ground with

landscaping. |

| One

idea of this project is that buildings for temporary

use can be set up quickly almost anywhere. These

can be used for schools, display and meeting facilities,

offices, housing - what have you. As example, if

we were to do an RDS [link] where

no space was available, a complex like this could

be set up in the parking lot of a hotel or shopping

center - even an open field [link]. |

| The

structure can be erected (one day) the berm structure

put in place using planter boxes and potted plants

(one day; see: EcoSphere Greenhouse [link])

and a level floor of brick over sand provided for

the interior

spaces

and the

patios

(one

day).

There would, of course, be no berms at the entries

and patios. Any number of domes and hexagonal rooms

can be provided in numerous configurations as required.

Power, communications and waste management are provided

in prefabricated self-contained unites that “plug-in” the

hexagonal configuration. Properly done, a building

like this can work for months with little or no maintenance

required. Because the building is light weight -

and the weight is so evenly distributed - the structure

will easily sit on whatever paving, gravel or compacted

earth that exists. Once this shell is set up, complete

with windows and doors, interior components are moved

in (two days). |

| For

installations of greater duration on unpaved ground,

wood foundations can be employed. An alternative

is to put the entire project up on a modular wood

platform, a prefabricated concrete footing, even

compacted earth or straw bale construction - or any

combination of these design strategies. Whatever

foundation and base wall treatment is used, the idea

is cause minimal disruption of the terrain (or built

site) and maximum

reusability of all materials. |

| The

interior layout would use the same kind of set up

of a typical AI/MG

Taylor environment [link] with

the domed areas used for large flexible work areas,

the hexagonal rooms

for more intimate, private spaces and the lofts for

sitting and reading areas. |

| The

dome and hexagonal room components are built of plywood

over wood and steel frames and provide a combination

painted and wood finish on the exterior and interior

- much like a wooden boat. The windows-skylights

are mostly in the hex shapes making most of the view

up and out and into the landscaping areas. Entry

doors, opening into patios, are made of wood and

glass to provide horizontal views into the contained

patios. In general, the language of the a typical

Usonian [link] is

employed. The interior spaces are large circular

domed rooms with the smaller hexagonal rooms with

lower ceilings (see: Schematic layout below). Second

level platforms are optional. The skylights-windows

can be placed to best make good views and appropriate

natural lighting. These windows-skylights have built-in

shades (see below) for control of view and light

levels. There is no compromise with this approach

between utility and architectural values. Most Pattern

Language [link] values

can be accomplished. |

|

|

| The

EcoSphere [link] project

uses the same dome configuration but employs a different

site strategy than what is described here. |

|

| In

all, great freedom of layout is accomplished that

provides the flexibility to make extremely useful

arrangements as may be required by many different

uses of the building. The entire structure can be

reconfigured if necessary. The nature of the structure

and the way that it is built creates a composition

of great strength. The structure is anchored to the

pavement or ground with steel pins which are removed,

and the holes filled, when the building is taken

away. |

| The

exterior finishes and waterproofing can be engineered

to last, at least, between one year and 18 months

without field work. In between deployments, the surface

skins will be be refurbished - as a boat is on haul-out.

This is likely a 30 day cycle at most. |

| The

cost of deployment will be about 10% of the capital

value of the structure which, itself, will be low

compared to many other systems. This deployment strategy

is practical in circumstances requiring time-to-value

compression [link],

when transportation is critical and/or when demand

ebbs and flows. It also readily

facilitates temporary use of land that is in “holding” waiting

development. This concept of temporary development and

staging the development of land through an economic

cycle based on its urban context has long been a

factor of our real estate development philosophy

[link]. |

| It

should be clear that the same thing can be accomplished

on undeveloped ground - the siting strategies would

be somewhat different. |

| This

system provides an attractive, useful, flexible,

movable structure that will last for years as it

is deployed from site to site - one that exploits

the feature of the geodesic dome while mitigating

its few but serious downside characteristics. |

| This

can make you wonder why “permanent” building

are so prized - and it should. In future years, the

distinction between “buildings” and “vehicles” will

fade. We will discover that buildings have to adjust

to site and circumstances in a far more adaptive

way then they do today - and, that vehicles are environments

that have to support more kinds of activities than

sitting on an uncomfortable bench, unable to work or relax,

while passively watching the world go by. |

Typical “Snowflake” cluster

of

two domes and pod units

|

| The

schematic layout above shows the diversity of space

possible with this configuration -it is a space rich

in both prospect and refuge. A high variety of functional

areas can be accomplished. This drawing

is oriented the same as the partial top view (but

is reduced in scale). The domes, using plywood construction,

can range in diameter from 50 to 75 feet making the

Pods about 15 to 20 feet across. The layout shown

has three Patios, three Entry/Exits, two domes (one

with a loft area) and 6 private Pods. In addition,

7 Pods are used for circulation and transition uses. |

| It

should be clear that this same kind of configuration

can be used for domestic living space or a combination

of domestic and office. Even small shops can effectively

employ this kind of configuration. |

|

Addition

to traditional house - July 1973 |

| In

addition to how the dome rests on the site there

has been few uses that properly treat and fully make

use of the interior space. In addition, getting in

and out of the structure (gracefully), and fitting

in with traditional buildings, has been a chronic

problem with this structure. Another design problem

is “fitting” the dome to more traditional

structures. The Section above shows some design strategies

for dealing with these intrinsic problems: |

| Surround

the dome with a landscaped earth berm that

intersects at the 2/3 curve plane of the

dome - this joins the dome gracefully to

the Earth and provides a landscaped band

around the structure. This landscaping can

be ornamental and eatable as is appropriate.

Exact view points and privacy (view and sound)

can be achieved with proper plant location. |

| Build

a central core that houses mechanical systems,

plumbing, fireplaces and electrical, vertical

movement aids (stair, elevators, etc.)

- penetrate the dome following the shape

of one geodesic “hexagon.” No

other penetrations (other than the entries)

will be required. This takes advantage

of the dome’s waterproof skin and

maintains it’s integrity. From the

horizontal center line of the dome, build

a bridge (open or closed is optional),

again following a “hex” shape.

This should be designed to fit the second

level of the traditional building (or other

entry portal). In domes of greater size,

it can be useful to provide and underground

entry [link] tube for security and esthetic

reasons. In the case of the dome shown,

which has a partially underground floor

level, build a descending stairway through

one portion of the earth berm. Now, the

two structures are connected and integrated

but visually isolated with landscaping

softening the negative space between their

two forms. |

| Cantilever

all the living space floor platforms off

of the central core and avoid contact with

the skin of the dome - leave this free

to be expressed as an “environment

valve.” This way, the geometry of

the floor platforms is “resolved” by

the negative space between the dome geometry

and the platform’s. There is no way

that these can be resolved with contact

- a series of ugly, difficult shapes, expensive

to build, is the inevitable result. Design

privacy into the layout by the vertical

and horizontal location of function spaces

(going from “public” areas to

more private and so on). |

| Design

the solid and glassed sections of the dome

with attention to sun and views. Light

the inside from the outside thought these

glassed areas which will provide shadows

at night, like in daytime, and enhance

a sense of privacy without having to pull

the shades. Note that “unusual” viewpoints

can be provided by this schema as shown

on the section Traditional building hold

viewing too much to the horizontal orientation,

looking out “up” and “down” opens

the mind [link] to

new experiences. |

|

In

the illustration shown, there are several levels including

a underground floor and platforms. The underground

level is the greenhouse, kitchen and informal eating

area. The next level up, the Entry, Living spaces and

formal dining areas (food comes through a vertical

lift which is a warmer). The platforms, above, are

sleeping and private work areas. Of course, in this

case, there is some program integration with the traditional

building to which the dome is connected. |

| The

dome shown is 25 feet in diameter. The useable space

is the entire sphere. The full potential dynamics

of the shape are used to the maximum and the usual

problems associated with a dome (conflicting geometry’s,

pie shaped rooms, stuff penetrating the dome at awkward

places and other misdeeds) are avoided. |

| Again,

these Design Strategies can be used for domes of

various sizes and to house a wide variety of functional

spaces. |

|

| In

a dome of 50 feet or greater, the interior volume

of the sphere is such that the geometrical options

become very great. |

| This

illustration is a space study for a multi-level combined

home/office and guest complex inside of a 75 foot

dome. |

| It

was conceived for a sloping site - the shaded area

(in the upper left quadrant) is where the dome goes

into the ground (Providing a heat sink). The rest

of the structure completes nearly a full circle above

the lower slope providing views of interest and a

variety of access points to the exterior. |

| Spaces

of great beauty and utility can be built this way.

The exterior shell is one simple statement made of

two elements: one solid and one “open” (glassed).

the interior elements which make up most of the building

do not have to deal with weather. Therefore, they

can be designed to be light and simple - they address

their own minimal structural requirements, and only

have to deal with sight line and arrangement requirements,

storage and acoustics; prospect and refuge. |

| Separating

the shell (environment value) and the complexities

of the interior, gives freedom to both. This a strategy,

by the way, that can successfully be employed with

structures of a more conventional kind. The result

should be integrated - this does not means

the elements have to be connected. |

Window

treatment - Snowflake Dome May 1976 |

| Another

generic design issue with domes is the appropriate

treatment of the skylight/windows. In the Snowflake

configuration, all the window areas are in the hexagonal

and pentagonal prefabricated pieces (but not all of

the hex and pent elements, of course). As noted,

these window elements can be placed with great care

- for profound effect, however, there remains a number

of issues: sun control, privacy, night lighting and

the proper framing of the window elements without

complicating the inherent simplicity of the dome

skin. |

|

| These

configurations provide the ability to place windows

exactly where required - something much more

difficult to achieve in conventional structures. |

|

| The

window treatment design deals with these issues by

creating a valence unit that fits in the interior

of the dome

after

the components are erected. The fixed glass of the

dome is a triangle in each hex segment and is simply

trimmed out as shown. The valence fits into the hex

and slopes inward, toward it’s center, at the

same angle as the dome elements slope outward. Around

the hex perimeter of the Valence, an indirect light

cove is built in that lights up this cavity at night.

This can be supplemented with exterior light poles

as shown on the “addition to a traditional house

Section” (above) and illustrated by the MLU

Dome below. In addition, built into this valence,

is a series of triangular shades that “close” by

pulling into the center (by electric motors). When

open, they expose their tips as shown. This shade

material is both insulating and shading. This careful

combination of lighting and shades creates a number

of options for dealing with light, views, temperature

and privacy. Note that the MLU employs this glassing

strategy and provides a built in ladder for roof

access. |

| The

MLU stand for Minimum Living Unit. I explored

this project, in November 1975, as an attempt to

define what could be the minimum cost and maximum

living accommodation that would make up decent, graceful,

affordable adaptable housing and small scale office

and retail units. There was - and remains today -

tremendous gaps in these arenas - gaps that are not

being addressed by conventional architecture-building-financing

institutions. Many prior attempts to use wood and

other accessible means and the geodesic dome have

a spotted record. Funk seems to rule. Some pieces

of great charm have been produced but few of sustaining

architectural quality. |

| To

achieve a better result, a grammar has to be derived

that intrinsically employs the shape of the dome

in a useful way. In addition, a building method has

to be created. I suggest that the boat building industry

has long ago created the tools, practices and components

necessary for this. Small, strong, endurable, beautiful

wooden buildings are possible and they can be produced

in clean, low production, low-scale, shops. Fine

architecture can be produced that is affordable my

millions, that today, have little choice regarding

the quality of their environment. |

| Of

course, it should be clear that a variety of alternative

energy, food growing and waste-management strategies

should be employed with the MLU. These will be documented

elsewhere but have to be understood and an integral

aspect of the idea. The cost of traditional infrastructure

systems is not affordable by affordable housing. |

bootstrap_to_space

innovation_process |

|

|

| These

projects have intrinsic value in themselves.

There exists other reasons for exploring their virtues,

and the “shell as environment valve” design

strategy, besides that of mobile and low-cost environments

in

today’s Earth-economy. Collaborative

living as illustrated in Domicile [link] and

Mega City [link],

is one. The “Bootstrap

to Space” strategy [link] is

another. |

|

| Innovation

is both evolutionary and discontinuous. What is necessary,

today, is to combine these two - often competing

- approaches into one harmonious method that

integrates present needs and long-term goals. This

is the “Getting HERE from THERE” strategy

that is so intrinsic to the Taylor System and Method. |

| Our

separation of low cost housing from large-scale building,

from transportation, from work habitats, from computer

technology, from our space endeavors, is precisely why we

sub-optimize all of them and fail, again and again,

to get the synergy we need for true advancement.

The division of architects, builders, engineers,

manufactures, developers, from one another further

fuels this problem. Does it really take an army of

organizations - each hostile to one another - to

build a simple dwelling? Is is really efficient to

treat, housing, offices, apartments, commercial structures,

transportation and space units as if they were totally

different arts? I think not. |

| The

biggest barrier to building this way - other than

social indifference - is the way building

is conducted [link] today.

This way-of-working [link] wastes,

at least, 50% of the money spent and 75% of the time

used in non-value-added activities. I demonstrated

this in the 1960s [link].

It has not changed in the last 35 years - in fact,

it has gotten worse. |

| The

purpose of a system is it’s output. Want to

change the result, change the structure of the process

- there is no other way. |

|

|

| The

EcoSphere Garden Project [link] is

an easy way to get started exploring these ideas.

Easy to build and productive;

it should pay for itself, in produce, within a few

of years. |

|

|

|

| To

MG Taylor Nashville Compound Project |

|

|

Matt

Taylor

Palo Alto

May 19, 1999

SolutionBox

voice of this document:

VISION • STRATEGY • SCHEMATIC

|

|

click on graphic for explanation of SolutionBox |

posted:

May 19, 1999

revised:

January 1, 2003

• 20000513.151824.mt • 20000616.151133.mt •

• 20000621.171330.mt • 20000701.908912.mt •

• 20000702.859134.mt • 20000829.321487.mt •

• 20030102.237761.mt •

note:

this document is about 80% finished

© Matt

Taylor, 1973, 1975. 1976, 1979, 1999, 2000, 2003

Certain

aspects described are Patented and in Patent Pending

IP

Statement and Policy |

|

|