the UNIT SYSTEM postUsonian |

| |

Outline of the Basic System on Three Levels of Recursion |

page one of four |

|

| The Unit System (not the name we will go to market with) postUsonian is usable through the full range from remodeling and adding to older houses, to shedwork units, to mini homes to “full size” (yet modest by present standards) houses, to co-housing communities. Foundations, decking (independent of Unit decks), and roofing (when units are sheltered and tied together under one Armature roof System) are field built; the Units themselves, the many interior functional packages that go into them, glazing and wall systems - which tie Units together when they form a complex - and the Armature elements which make up the large sheltering roofs (when required) are prefabricated. All of these prefabricated elements are of the general scale incorporated in the large AI navCenters now being built therefore within prototyping and low scale production capability of AI today. The principal new production requirements for the shop are waterproofing, plug and play electrical, plumbing and HVAC systems. Many of these systems can be purchased and installed at the point of production or in the field as circumstances dictate. |

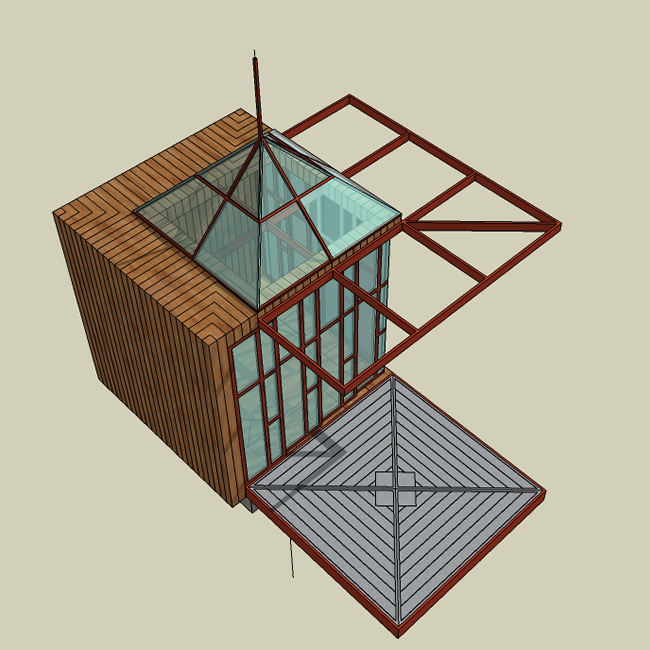

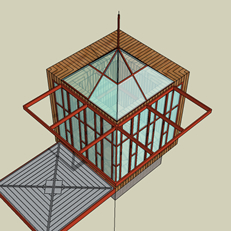

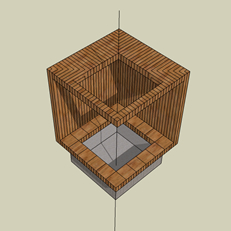

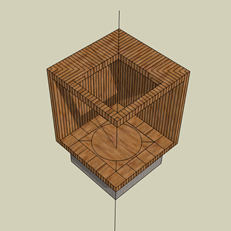

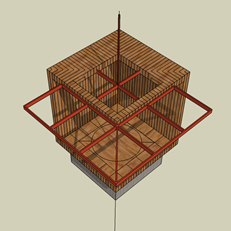

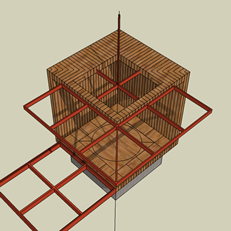

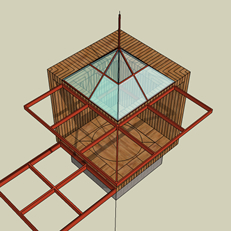

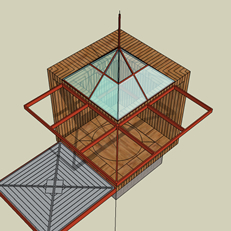

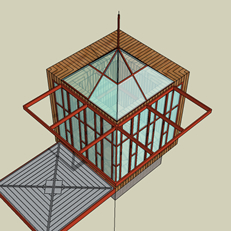

| This basic Unit - recursion level 2 - is at the center scale of the three levels of recursion of the complete Unit System design. A single Unit - which is a 12x12x12 feet net interior space can be a stand alone environment or a “room” in a larger environment. Various prefabricated component packages - recursion level 1 - provide the specific functionality required. A Unit can be a mini living and work environment, a workspace, a sleeping room, bath, a food preparation room, sitting room or many combinations of these. The Units themselves, as will be shown on the following pages, can be put together to create a variety of larger spaces. Different sub-components for skylights, window-door walls, trellis arrangements, decking materials and patterns, can be provided with all fitting with the basic structure shown on the right. The decking shown is one arrangement of many. There will be recursion level 1 components for the outdoor areas just as there are for the interior spaces. There are a variety of options which, combined in different ways, will make a number of spaces - both “interior” and “exterior” - depending on their configuration and intended use. |

| The third recursion level is an Armature System which can span over several Units and be roofed and enclosed - or not - depending on requirements and the location of a given project. This way a “house” can be made or a series of Units (or clusters of Units) under a sheltering trellis or roof. It is possible, as example in a mild climate like Northern California to have each “room” detached from one another and at different levels connected by paths and deck in a garden under a high roof and trellis. In a more server climate, the sliding door-window wall system can connect these spaces as desired. With a system such as this, a house can grow as the family does. A remote shedwork cabin can evolve into a house for multiple generations over time. The possibilities are far greater than provided by the prevalent box divided into many smaller boxes design strategy. |

| The basic Unit itself, for these reasons, is designed and manufactured more like a boat or RV is - except for appearance - and is self contained (for whatever its function is), is weather proof and provided with storage/service walls and floors out of which sleeping areas, lofts, work surfaces can fold up/down/out as needed to make each space provide specific functions to specific occupants in the way they desire at any moment in time. These systems, because of their modularity and use of hardware, can be easily retrofitted to accommodate changing needs. |

| The basic Unit as the middle scale of three layers of component building, is a platform. As such it encourages designers to build “apps” which fit within and employ the “operating system” of the entire Unit System thereby expanding the grammar further without corrupting it. By following the 4 level MG Taylor marketing schema: 1 - providing plans and license; 2 - detailed fabrication shop drawings with optional design and project management services; 3 - the fabrication of components; and 4 - turn key services, Owners, assisted by a ValueWeb of providers, can involve themselves to the degree desired thereby building out and evolving their habitat at their own economy and pace. This approach also promotes different forms of ownership as well as land use. These options will be explored on page 4. |

| There are four layers in a house or complex scale Unit System postUsonian: inside-inside; inside-outside; outside-inside; and outside-outside. These layers are the degree which the human created and Giaia created realities mash into one another. |

|

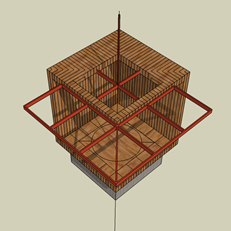

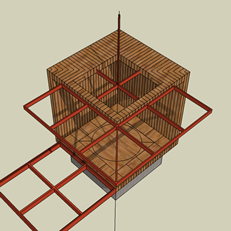

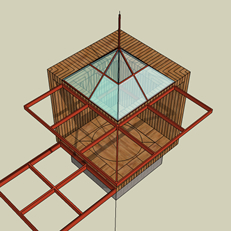

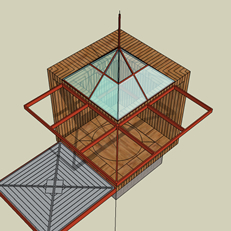

| assembly of the BASIC UNT |

|

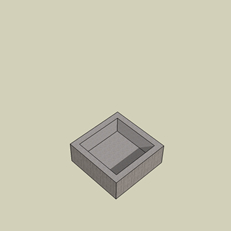

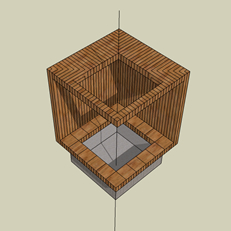

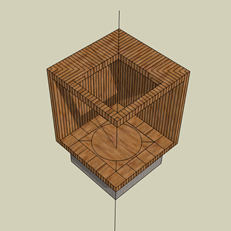

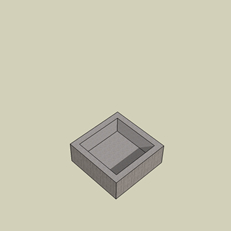

Assembly of the Basic Unit is achieved in about 12 steps eight of which are shown here. A basic concrete coffer is placed in a gravel bed or on piles/footings as soil requirements and loads dictate. Each Unit has its own foundation which is wired and equipped as required to serve a variety of functions.

The coffer can be used for storage, equipment, a sunken sitting area and/or bed, a bathing tub, a elevating table and so on. In front of and out of the solid walls, modular storage units, work stations, fold down beds, loft areas with storage or work stations under them achieving any necessary function - these are crafted out of a limited number of recursion level 1 sub components. Different finish surfaces bring variety in color and texture, as well as, best characteristics for meeting utilitarian requirements. These sub components will be outlined on page 2. As in a custom boat, every surface, floor, walls ceiling,is a keeper of a function and can be arranged in different ways.

The Unit is a compost steel and wood structure, insulated for temperature and sound and wired for radiant heating. This fabrication allows it to ship in flat components in road shippable semi-complete assemblies and in the right circumstances as a fully erected unit. This structure also allows the attachment of trellis and deck structures. These frames can be dressed with a variety of trellis and decking materials and patterns fabricated or field built. The trellis a decking frames can also be employed as a means to attach two or several basic Units together to form a larger building. Connecting walls can be made with modular panels or the sliding glass door system. Some of these variations will be shown on page 3. A living workspace can grow, evolve and be re-purposed over time without great wasted cost and effort. This capability combined with new energy technologies and use patterns supports a new paradigm of use, ownership and how human construction is done on the Earth.

Light from many sides of a room; light which is oriented in the daily cycle properly for the functions a space primarily supports; light and no light, shade and shadow; these are primary aspects of a healthy living environment. Basically, this design provide light from three sides of the cube and opaqueness from the remaining three. How a Unit or a cluster of Units are place in relation to the sun is an important design decision. The traditional large box divided into small boxes approach, especially on small building lots, makes it difficult to orient each space in just the best way. The simple foundation and small footprint of the Unit provides significantly greater flexibility than standard approaches. The skylight not only provides natural light from the top, it also, because of the added height, enhances loft areas. Living and work spaces are too often “flat land” in their nero linguistic reality. This and their general lack of texture, natural light and shapes which delight and have meaning make the environment, which most people live and work in, to be perceptually and conceptually impoverished.

The sliding glass door window wall opens the Unit to the many different spaces beyond providing the prospect to the refuge For many sites and orientations, as well as the preferences of individuals, sound, light, heat abatement screens will have to be provided. This will not always be the case if the landscape is adroitly employed. Default habits should be avoided. This is new ground and the opportunity for people to experience their self created shelter differently. |

|

|

|

|

|

|

|

|

|

| Over the last 54 years (as of 2010), I have played with the “cube” module many times from 8 foot, 12 foot to 20 foot sizes. I hardly know an architect or designer interested in modular or affordable housing who has not. It is an attractive concept yet one with both many opportunities and difficulties. The “cube” provides an armature and at the same time can easily become an over structured trap. |

| For this version, I selected the 12x12x12 foot net inside dimension because it provides a high potential unit functionality, good height - which can be used in a variety of ways - at the basic unit level, and the ability to combine in many articulated combinations to provide larger yet still intimate spaces. The wrong-sized module can be too small for many uses yet quickly add up to too much space before the program requirements are met. For complex solutions, all three of these modules, 8, 12, & 20 feet, can be employed individually, mixed and combined. |

|

| This phase of the postUsonian UNIT SYSTEM development will test out both the module sizes and the method of fabricating, shipping and erecting of these modules to see if they make sense economically. I have little doubt they can make a good piece of architecture for many - and, that they can be made to sit lightly upon the earth - yet, the question remains if they can be executed within the means affordable to a large number of people within the present economy. The design and engineering questions can be answered with drawings and calculations. Costs can be estimated from this level work. Some prototyping will be required to make sure that the logistical and field erection processes will work as intended. |

| Because this is a modular system, it will be possible to field test the system by building “shedworks” and similar small additions and stand alone works that are configured to satisfy a variety of living and work scenarios. |

|

click on the drawing below to go to the Cube Patio Unit Site |

| Go to my Facebook page RMattTayl [link: https://www.facebook.com/RMattTaylor] and look for “WHAT’S IN A NAME” postings to follow and Participate in the dialog to give the Cube Patios Unit System its product name for when it goes to Kickstarter and to the market. This dialog will continue until 10/26/12, when a name will be selected. |

| This process of naming the project is important. The name becomes the meme, the icon in the public mind of what this approach to architecture is and means in this time and place. The Naming is a first step in preparing the Cub Patio Unit System for a Kickstarter campaign to engineer, fabricate and prototype three projects, with three different users, in two climes and for three different application markets. This provides enough variety to set out a number of interior configurations and technical systems. |

|

more coming - page 2, 3, & 4 are not yet populated with content |

|

SolutionBox

voice of this document:

VISION • STRATEGY

SCHEMATIC |

| |

click on graphic for explanation of SolutionBox |

|

|

| Return

To postUsonian projects INDEX |

|

|

|

posted: August 25, 2010 • revised October 20, 2012 • 4:50 PM @Elsewhere |

copyright© Matt Taylor 2010 • Matt Taylor, rsmArchitecture 2012 |

|