| VCBH NavCenter

Development

April through September 2002 | | | | Concept: April 25, 2002 | Start: May 15, 2002 |  |  | | Install: June 2, 2002 | Use: June 6, 2002 | Design-Build-Use Process | | The Vanderbilt Center for Better Health is employing an MG Taylor NavCenter to further develop their Rapid Advance Methodology (RAM) and to deliver Infomatics technology to their ValueWeb members in the Health Care Industry. This process is documented elsewhere (password protected). This document captures, in real time, the history of the FasTrack Design-Build-Use process as the NavCenter - which will be called the VCBH Innovation Center - is created and the early use of the environment as it is brought into full use. | | The “box” in which the NavCenter is being placed will, in this first phase, have minimal work done to it. Painting, cleaning and re-stretching the carpet and upgrading of the hung ceiling tile over the main large group process area (Radiant Room) is the extent of it. Two reasons drove this decision: first, the aggressive schedule of getting the facility ready for first-use in less than 30 days after the “go” decision. And, the desire to evolve the permanent work-habitat based on the experience of real use - not a guess of what “should be.” It is thought that experience may bring significant changes to the expected scale and scope of the project. Yet, initially just installing a RDS level facility for the first phase was not considered adequate. The key to finding the happy-medium between a completely built-out architectural space and a totally portable one was the creation of an entirely new level of Armature. This required the rapid-Prototyping, from a first sketch of an entirely new system of architectural-scale furniture and successfully installing the first iteration of the product in less than three weeks. Part of the functionality of the furniture system had to be the ability to work well and look “done” upon opening, yet, be able to evolve through iterations of migration from a mostly “portable” to a mostly “permanent” installation. | | This rapid-Prototyping, FasTracking, iterative approach to developing a workspace makes a great deal of sense in today’s business environment. The AI Foundation II series WorkFurniture system is the only one, that I am aware of, that provides this flexibility while maintaining the capability and look of ‘being done” at each step along the way. | | In order to meet the schedule, AI manufactured and installed the Armature System and installed an existing RDS to provide capability while the WorkFurniture for the layout below is being produced in the 6 weeks following the opening. This experience has already provided feedback that has resulted in some design adjustments. | | |

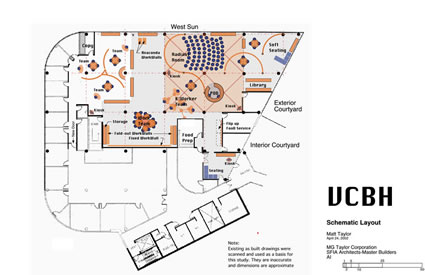

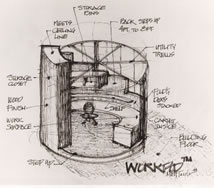

| | April 24, 2002 schematic layout of the NavCenter | | | There are a number of old AI - and some new ones - that have been newly reinvented and redone in order to meet this specific challenge. The Tracery aspect of the Armature was brought to an entirely new scale and level of development. In this case the design employed in the Cambridge project in 1998 was restated and made considerable lighter and more adaptable. The Octopus received it’s first full reworking since it was first designed in 1996. The Cube-Pod (a first development from 1990 and 1995 designs) is built for the first time. The ceiling docking power poles were recreated using the Gatling post that was developed for glazing in our Cube Office System in 1999. Several new docking components and rolling bases were refined to create a new level of dock-ability and a refined trade-dress. | | The AI Armature System is made up of an number of components. These are profiled below as they progressed through the stages of design-development, installation and first use. | | | Cube-Pod System - photos: June 4, 2002 |  | | The Cube-Pod is new and was developed for this project. We have long wanted a simpler version of the WorkPod that will “plug and play” into the other Armature elements and WorkWalls and roll as a single unit once assembled. One person can relocated this “office” fully loaded. | |  | | This version of WorkPod is close to the first version I designed in 1990 which is smaller and less expensive to make than the more sophisticated 1997 version we prototyped and installed in several projects in 1997 and 1998. Both have a role. | |  | | The original 1990 Pod concept was re-developed in 1995 for the proposed Vanguard Center which was not built. | |  | | The cube elements of the pod are interchangeable and can be single, double, open glazed of wood filled. The top ring acts as a lighting armature and connects through one of the gatling posts to the Tracery to access power, LAN and A/V to the Pod as required. | |  | | The top ring “floats” above the vertical Pod elements and visually “docks” to the horizontal Tracery. Integration and independence is achieved. | |  | | The Armature System bridges the gap between human scale and building scale. It provides a variety of elements than can be used to solve storage, logistical, navigational and space identity issues. It creates prospect and refuge, team and large group spaces | | | Tracery - WorkWall System - photo: June 5 |  | | The Armature integrates with existing structural elements providing them an architectural character often lacking in typical “developer” commercial building. | | | Monitor Tree - photos: June 5 |  | | The Monitor Tree supports three small and one large flat screens that can display video, data and satellite feeds. The Tree roles easily and plugs into various ceiling feeds that provide multimedia and computer input and output. | |  | | The Tree can plug into a ceiling (note the birch panels in place of a ceiling tile) feed or into a Tracery leg.The entire assemblage rolls and has wire management built-in. | | | First Use - photos: June 6 |

| | The Entry to the VCBH Innovation Center is off a 7 story open Atrium. A glass wall and doors create a transparent boundary to the space. | |  | | The Entry creates a simple, inviting space that does not broadcast what is to come. It brings you in to a comfortable, intimate and neutral room. | |  | | The carpet, with a Prairie School motif, anchors the center of the room and pulls the eye away from the more prosaic elements of the existing “box.” This “room within a room” device hints at what is to follow. | |  | | A single wall of strong color, a sign leads to the overly narrow (existing) opening to a narrow hallway. The design question was how to “use” this circumstance to advantage. | |  | | The answer: keep the light levels low and introduce Tracery elements that frame the greater space beyond. Three carpets create a path within the tunnel which leads to what now seems like a greatly expanded space. | |  | | The VCBH Innovation Center’s first users enter the environment for a work session. This is the diagonal view 180 degrees from the entry tunnel. The column with the “ G” Posts is the center of the large area defined by the Tracery elements (toned on the plan above). | |  | | Conference participants start to explore the space which has an abundance of prospect and refuge. | |  | | Books, displays, toys, tools, work areas, informal areas, open areas, nooks... Each individual finds a place to comfortable for them - a place to venture forth from. | |  | | Within a few minutes the Center was in use with one of it’s intended purposes which is large group interaction and collaboration. | |  | | The VCBH ValueWeb dialog begins... Prospect and refuge combine to form a creative PLACE. Elements mostly lacking in the so-called modern workplace. | | Picture Gallery of the building and first use of the VCBH

by Alicia Bramlett | | | The VCBH Innovation (NavCenter) will support a wide variety of research and client support work that will require detailed project management. An area dedicated for that function was installed by the AI KreW on the 22nd and 23rd. This consists of a “U” shaped area with a large adjustable Team Table in the center. The center 24 foot WorkWall facilitates strategy AndMaps and the side WorkWalls Time and Task Maps. On the backside of these walls are storage bins for support materials and project materials. The side 12 foot WorkWalls swing out to expose an additional 24 linear feet of work surface on each side. When open they “enclose” the area to priovde more intimacy. In total, there is 876 square feet of working/display surface provided. Enough to develop and show a project in some detail. | | | | | The Tracery fascia board brings scale to the space and provides structure for 12 volt lighting. | | | | | The Work Team table is composed of a center piece that functions independently or accommodates a number of large and small AI tables. This way, a number of different subgroups can work while still having easy access to the energy and information of the larger team. | | | | | Looking into the Project Management Area from the KnowledgeWorker Support Team Area. | | | | | The ceiling lights will be recycled, over time, to full spectrum lighting; this along with the 12 volt lighting (now being designed) will improve the color signature of the space. It can be seen from these photos that this is necessary - particularly this far from the windows. | | | | | On the right hand side: storage bins, WorkFurniture Storage and Exit to the Stairwell. | | | | | On the left hand side: storage bins and Exit to the internal hallway. Both these side spaces are different in dimension and in the location of their exits. | | | | | Looking back from the Project Management Area at the Entry and Pod. The KnowledgeWorker Octopus Workstation will be connected to the wall, on the right hand side, past the corner completing the transition between the open areas and the Project Management space. | | | | Spaces should have continuity, yes; They should be flexible and able to multitask, yes; AND, each niche must support, indicate and reflect the kind of work that is to take place within it. It must, to be effective, provide the appropriate tooling and ambiance for that work. It has to be specific - not generic. Those who work here will remember their experience and work in context of place - The architecture you see here goes beyond utility. It it not, however, decoration. It is ART and as such has a practical role in the workplace. Everything SPEAKS and NavCenters are one of the few places where this is recognized and used an an active principle of the design and the management of the environment - and the work that takes place within it. | | The VCBH Innovation Center (NavCenter) has several major functions that require a unique setting: research, knowledge-management and archiving, collaborative design, project management, venture management and promotion, rapid-prototyping, education delivery and learning, multimedia production to name some. These functions require that large group, teamwork and individual work can be done discretely (and in parallel in various parts of the Center) and with everyone being able to shift mode at a moments requirement. In addition, technology has to seamlessly support all of these work-modes and employ the 10 Step Process making the entire environment a knowledge-factory. |  | | 1982 MG Taylor technology vision. Teams working in multiple modes their work augmented by multimedia - all interactions documented, shared properly and archived. | | | The following photos, of the installation process, show how quickly and easily the system goes in and the transforming effect that it has on an otherwise prosaic space. A box of no particular distinction has been made to fit a specific function by the employment of modular furniture with a dash of local adaptation. We use wood because of its many qualities: strength, flexibility, durability, warmth, reparability. It also allows us a “lean” mix between manufacturing and custom response in a way that is both sustainable and affordable. | | This makes a “System” of manufacturing but not in the usual sense of common usage. SYSTEM in this context refers to the entire organizational effort and design and manufacturing and operations and client participation (and using) in the making of the total environment over time. | | | This Tracery piece, which matches other pieces previously installed in the space, is being attached to the hung ceiling. | | | | The Gattling Posts and their column ties are installed. This echoes the grammar used in the group process spaces. | | | | By keeping the pieces separate from the column, yet integrated, the impact of original construction irregularities is greatly minimized. Product is made to precise dimensions - error “taken out” in the gaps. | | | | In go the arches and the storage units which are placed on a leveling base and remain free of any other building contact. | | | | WorkWalls are started on the inside of the storage units. The back of the wall making the back of the unit. Half-section “G” Posts are placed on the far wall to receive arches. | | | | Installation of the “hanger” for the wall mounted WorkWalls. | | | | The Tracery piece and Storage unit/WorkWalls are complete. | | | | Second level Tracery installation starts. The space takes shape. | | | | The long WorkWall is complete and the fascia is started. | | | | G” Posts and wire chases complete the work. | | | | | The AI Shop went from final design to complete installation of this phase of the project in about 10 days. The same workers who did the manufacturing did the installation. Immediate feedback without need for management intervention. The Shop is also deeply involved in the design process and develops final CAD drawings for all products. In total, idea to design to engineering to building and installing is a seamless process. And a fun one. | | The Project Management space now fits with the group process areas installed a couple of weeks before. The entire environment is just beginning the process of settling in as the owners start the process of making it their own. Already the environment is starting to evolve as the USE process begins. Living environments can be designed - and they can be constructed. They come to life - when the do come to life - because of how they are employed. The architect-builder can make the potential. Only those living in the space breath life into it. | | | | Once a grammar for a project has been determined, there then exists a reservoir of “patterns” that can be applied to localized design and “fitness” problems. This informs and delimits the design decisions that are made along the way from inception to completion. This simplifies the design process greatly. Unique and well integrated environments are conceived and built in less time than most organizations can do the design and engineering. This design “smarts” is embedded in the entire organization and every person in it. Besides providing organizational efficiency this way of working makes “job enhancement.” It is just more fun to work where thinking is required and you can make what you think about become real in concrete FORM. | | This way of working and the FasTracking, design-build rapid-Prototyping process is the process that the NavCenters are created to facilitate in the broader reread of the user’s work. The fact that they are built by the same process they promote is not lost on the subsequent users. It is a proof of concept thing. Would you ask an organization to bet their future on a process that failed to work when building the environment in which the work was to be done? | | NavCenters are places of integrity. They have to be in order to do their work. Every aspect of their creation and use must reflect this principle. They are environments where certain attributes are demanded of the user. They must be invention, innovation, quality, playfulness, study, dialog, production, economy. They must be the result of collaboration, Design/Build/Use, rapid prototyping, FastTracking. An environment is how it is designed, built and used. | | | The final install of various sections of the layout started the weekends of July 27th and August 3rd. The final work will be completed August 10 in anticipation of the VCBH Open House on August 12th. In total, this work includes the installation of the Octopus Workstation in the KnowledgeWorker Area, the Star Wall for the Research Team areas, The rolling/folding Anaconda Wall, Rolling Book Case/Workstation Units and integrated 12 volt lighting fixtures. | | The Octopus is a horizontal rolling Armature that creates an easily adjustable set of work niches where Wings and other Workstations can dock. Power, LAN, phone, video feeds are provided from one source - in this case the wall. | | | | The Octopus creates a space within a space; it defines a vertical and Horizontal domain - defined yet open. | | | | Adjustable bookends sit on the top rail allowing resource materials to be close to the various “docking” work station wings. | | | | Octopus wall detail - the feeds come in here - looking toward the Project Management area. Foreground, middle ground, background on every axis. | | | Since the June 6th opening day, The VCBH Innovation Center has been setting up systems, holding Discovery and Sponsor Sessions and training. The first full up use of total Center capability will be in September when two DesignShops will be done - one for an internal Vanderbilt project and one for an external Vanderbilt client. Two back-to-back DesignShops make a robust test of any environment and its support systems. The VCBH will have gone from an idea to a fully capable system in four months. The first cycle (by no means the last) of Design/Build/Use will be complete. | | The complete transfer process of the Taylor methods and the integration - and reinvention - of these methods into the VCBC RAM system of work will take about a year from this point forward. This transfer is accomplished by a combined team of VCBH and MGT KnowledgeWorkers learning and working together. Robust capability exists from the beginning. This starting capability is transformed through experience and use. It migrates from the general (the sum of all past experiences) to the specific (what is required for full efficacy at this installation). Over the year, the MG Taylor KreW shrinks and the VCBH KreW grows. NavCenters are created first by cloning and then matured by transformation. The process of making a NavCenter is the installing of a dynamic OS that then recreates itself. It should be clear, then, why this has to be done quickly. | | A touch sensitive light switch for the 12 volt lighting at the entry “tunnel.” | | | | Brian Ross assembling the first 12 volt light fixture for the Entry “tunnel.” | | | | Three of the lights in place. Also note the newly installed flip-up serving tables for refreshments and materials. When the lights are lifted off their track, they turn off and on again when placed in a new location. A simple solution that makes “track lightin” truly adjustable - at last! | | | | Copper, wood, glass - light and design - combine to make an easy to move custom fixture that reflects and reinforces the architectural theme of the Center. | | | | This lighting is the result of a collaboration between PipeDreams and the MG Taylor AI production Krew. It builds off the earlier work done on the Joseki project. We have wanted - for years - to more fully integrate lighting with our WorkFurniture and Armature systems. Joseki, Vanderbilt and the SDC projects are our first major inroads to this ambition. The PipeDreams idea is to engineer a basic infrastructure (out of common off-the-shelf components and copper water piping that anyone can install) and to encourage the design of a wide variety of hand-crafted fixtures that have artistic as well as architectural character. All this promises a far better product at a fraction of the price now provided by the lighting industry which tends to be expensive, unimaginative and narrow in the range of their solution sets. | | The WorkFurniture installed at Vanderbilt exhibited many new designs. In addition several old “standards” were refined. The round table received a new method of attaching the top to the legs (iteration 7 or 8, I think) and also came with a design developed a couple of years ago but just now built for distribution. In this version, the legs stay attached to one another and fold for storing. They attach to the top by a screwed mechanism that also doubles as a wire hole to the top. The legs are “pulled” tight to the top making leveling much easier. |  | | How many tables look this good underneath? Well, got that one done at least! I first designed this table in the early 80s. Langdon Morris, Bill Blackburn, Brian Ross and Paul Lyon all made improvements over the years. This is the most refined version. The idea of the table is to be easily set up, taken down and stored. | | | | | The 12 volt lighting system installation was mostly completed By the 10th of August AI work session. A few refinements are to follow. The lights make the Armature System seem “tree-like” and combine ornament and utility making a semitransparent layer between ceiling and human-occupied space. This enhances the sense of shelter of the space and obscures the more mundane aspects of the preexisting ceiling “system.” It will be possible, now that these lights are installed, to re-switch the existing ceiling lighting so that these lights can be on full, on 75%, on 50% or off. This will provide variable lighting levels suitable for different activities and moods at different areas of the space at different times. The existing fluorescent bulbs will also be changed out to full spectrum tubes over time. This, with the 12 volt lighting and a greater reliance on natural window lighting, greatly modifies the light signature of the space. Modern workplaces are usually over lit and fail to differentiate between ambient, general, task, highlight and effect lighting. This oversight typically creates a washed-out space that offer little variety and visual relief. Both prospect and refuge are sacrificed. | | This installation of this lighting system is the second iteration, in as many months, of four projects. | | | | The VCBH had its open house and reception on the evening of August 12th. This was the first opportunity for the wider Vanderbilt community to see the space. bill_stead | | Bill Stead welcoming visitors to the VCBH Innovation Center. Bill is a leading proponent and innovator of Biomedical Informatics and driving force behind the VCBH RAM process. | | | | Cyril Stewart (right) is an architect and Dir. Medical Center Facility Inventory & Planning Space & Facilities Planning at Vanderbilt University. | | | | | In September, The VCBC Innovations Center did two back-to-back DesignShop events. This was the first full scale test of the facility as a system. | | This experience completes the the first phase of USE. Essentially, there were no surprises. Everything performed as expected. | | | | The VCBH Design/Build/Use process demonstrates that several methods and approaches often thought to be inimical can in fact be integrated into an iterative and seamless way of building. | | Christopher Alexander has pointed out the architecture is often better accomplished when buildings evolve slowly over time. I agree with this. Steward Brand wrote the seminal book on the subject How Buildings Learn. In seemingly juxtaposition to these viewpoints is the reality that modern finance and business demands requires very rapid and complete building processes. This approach has been responsible for a great deal of the environmental atrocities now spread around the planet. My contention, however, is that this is the result of a misuse of rapid design-build methods and is not the inevitable result of the technique. I have been employing extreme time compression in building for years without sacrifice to design or sensibility. | | The resolution of this is in the integration of the approaches and by imposing a rigorous iterative Design/Build/Use process and by employing a true ValueWeb in high frequency collaboration. | | We did evolve the design - and changed it - throughout this project. The environment will continue to develop for some time to come. It takes a year of extensive use of an environment of this kind to even learn its many possibilities. Each insight will suggest changes and additions that further augment the environment. Many contributed to the design and its execution. Their contribution comes from their own unique perspective, the actual work they do - and how they do it. All aspects of USE feedback to the ongoing development of the work. | | A flexible approach to building flexible environments requires a great deal more disciple than conventional methods. Conventional methods are control focused and seek to limit variety. This is why they are so often dull and prosaic. To achieve an organic response means to increase variety; it means to release control. It requires the discipline of systematic EMERGENCE. | | This project was started along with two others. All three projects are different in scale and location. Each, however, involves a community - a ValueWeb. Each explores a different aspect of making a new way of building. Each is an unique expression and each draws from not only my 46 years of experience but from roots that go far further back in time. | | | Matt Taylor

May 21, 2002

Palo Alto

SolutionBox voice of this document:

USE • LOGISTICS • PRODUCTION MANAGEMENT |

posted: May 21, 2002

revised: September 20, 2002

• 20020521.027356.mt • 20020622.199021.mt •

• 20020608.111199.mt • 20020609.876519.mt •

• 20020625.659982.mt • 20040804.209981.mt •

• 20020813.777661.mt • 20020818.222201.mt •

• 200209.123409.mt • note: this document is about 99% finished Copyright© Matt Taylor 2002

Aspects of the work shown and described are Patented and Pending by iterations | |

|