GoTo: for schematic design documentation |

| The mediaPOD design was stimulated by two client projects, a long held desire to create a POD configured to “fly” through a media rich content world, and a third project which “arrived” a few days after the mediaPOD was sketched out and described schematically and has now morphed into a renewed MG Taylor interest in the RDSx project. The Design Development process, which is documented here, will be informed by these applications as well as other future possibilities which come to mind. |

| The first project was eSpaces [future link ] a new rendering of office hoteling. The second, UVA Radiology [futurelink] which is looking for a POD-like solution for viewing medical e-rays. The third is a wonderful project which we may or not be able to participat in depending on its final business model [future link]. These projects and their requirements, along with my IPIAP and Stanford talks future links], remind me of Heinlien’s “it is time to railroad” quote [ future link]. I think it is time to CyberCon [links:]. |

| The core of MG Taylor’s Method is the integration of environment, work processes and technology to provide human augmentation which facilitates Transition Managers in their work [future link] thereby enabling them to remain requisite with the rapidly increasing change and complexity our society has created and now faces but has not prepared for [link: a future by design not default]. To do this, we engage, facilitate and practice the entire creative process [ future link] which is design (including research), build, and use. |

| The core of MG Taylor’s Business Model is to reduce to practice ideas, authenticate them by creating products and services in a market (often having to create the market), working through the economics - profit, non-profit and ecological - of the offering and then export the refined product to organizations who function as users, customers, partners or license holders who employ our IP as part of the offering of their enterprise. Many times, the result of our work is given as a gift to the world be that via publishing or by our support of non-profit ventures and their projects. This business design strategy is how we achieve ubiquity, while keeping our focus tight, even though the range of our work is extraordinarily broad by traditional business standards. As an action research and rapid prototyping organization, our long term economic viability is achieved by earning operating profits - as we take projects through their proof-of-concept phase - by ownership participation and royalties from organizations who employ our IP&C, and by revenues from teaching and publications. To be profitable, this requires a balanced portfolio of projects spanning their entire life-cycle. This is not an easy business model to manage. It is the only one we have found to be consistent with our mission [link: mg taylor mission]. |

| Given this, if it is time to “CyberCon,” the first step is to produce an integrated environment-process-technology product in the smallest package possible, while maintaining as robust an example of the CyberCon potential as possible, and thereby opening the door to the greatest number of future products as possible while bringing the greatest value to users across a broad range of applications as possible. |

media_pod_development_documentation |

| This intention, along with the three project’s requirements, sets the mediaPOD design specifications - a refined description of which follows as the first step in the Design Development [future link] process - for the mediaPOD. Following the these specifications, will be the documentation of the mediaPOD history as it evolves from idea to product to market to general use. |

|

mediaPOD Design Specifications |

| Installable and movable by the end user in a few hours without special tools, knowledge or skills. |

| Adjustability of multiple screens and and accessibility to media control keyboards/equipment. |

| Seating for four to five adults with adjustable foot rests and working surfaces. |

| Adjustable ventilation and heating (where required). |

| Outside panel access to large, key, fixed equipment components and wiring. |

| Fit within 9 foot ceiling and 10 foot 6 inch footprint. |

| Adaptable to a high variety of individual work and team meeting/work configurations. |

| Iconic image with strong identity and the ability to express an individual organization’s Trade Dress and brand essence. |

| To retail, turn-key, at a cost equitable with a typical furnished, equipped office of the same size/capacity. |

|

mediaPOD Design Development |

| Construction of the MULE (a pre-prototype full scale model) started the first week in October and was completed the first week of November, 2007. During this time, I made three visits to the shop to work with Rodney, Mike, Patsy and the AI crew. The UVA presentation as conducted on the 6th of November. |

|

| The angularity of this configuration makes a strong presence in a landscape of typical work stations yet its linearity makes the “fit” easier to achieve. The higher frequency configuration will require greater “buffering” with plants, lighting, etc., to accomplish the same “fitness.” Both, however, work. |

|

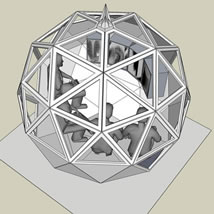

| The configuration shown above was my starting design for the process. This changed early on as Rodney selected a higher frequency configuration for a variety of reasons principle among them was to get the geometry to work for build-ability. The MULE was cut out of flat stock MDF board. There are advantages to both frequencies. As shown on my drawing, the lower frequency provides a crisper profile and larger glass areas. The higher frequency configuration (see below) provides a smoother interior space and makes the hexagon and pentagon components smaller and lighter and thus easier to move around and install. When we build the prototype and production mediaPODs, the profiles around the glazing will be narrower than on the MULE, as they will be built from wood stock not panels. This will provide a greater open feel to the space although it is already fine as it is. |

| On my second visit, October 12th., the basic dome structure was assembled. This allowed us to “work physical” while designing the ergonomics of the seating bench and the Armature arm and adjustable media work surfaces. There are some design tasks which are better done in real time, real-size with real materials, than pencil and paper - or computer - can facilitate. A designer or architect without a shop is missing an arm and a leg. |

|

| The first confirmation of the scale of the mediaPOD and the space within it. MediaPODS will cluster nicely and achieve a high level of density while providing privacy, sound isolation yet a sense of community. Dilbert is dead. The mediaPOD is an interesting simultaneous exercise in prospect and refuge. |

|

|

| Iteration one was put together with hinges. It was necessary to devise a way of holding the structure together while allowing fast reconfiguration of components and rapid take down and assembly. We devised a pin and hub system that met these criteria. This view illustrates the pattern on pattern of the design. |

|

| During this session we discussed a number of issues: the hub-connection method; the Armature, functional shelving and seating configuration;location and movement of the screens, the configuration of the glazing, the angle of the base, and possible trim details. Also, the logistics of getting the mediaPOD finished for the anticipated visit by UVA. |

| The MULE, at this point, radically demonstrated that the interior space was going to read “as generous” and that the requirements for screens and viewing could be readily met. I was still not certain if the lower or higher frequency of the geodesic dome was the best. There was the growing feeling that we had something going for us with this concept. The basic premise of the mediaPOD, that a three dimensional spherical arrangement was better than a circular “tube” - layout like our other PODs - was clearly confirmed. |

| On my third visit to the AI shop, on October 23rd., we selected colors and refined our monitor support system, as well as, the Armature skin. I selected “Arts and Craft” movement colors as they are sympathetic with the natural woods from which the production units will be built. Also, these colors go back to the very beginnings of the architectural tradition of which I am a descendant and believe should be a stronger force in our world today. |

|

| view of the basic profile of the mediaPOD. before painting and glazing. The connector nodes - which we will make lighter and smaller in the production model - will connect the modular components together. The raised floor and base will allow a turn table which will be useful for some applications in a landscape of PODs. |

|

|

| A simulated view of the X-ray screens. This is the essence of the UVA application. The monitor shelf moves forward and back and swings right to left to make viewing easier without forcing the users into unconformable positions. In production models, the glazing will be in three degrees of color progressing from darker to lighter. |

|

|

| The light ring is placed below the dome. It provides effective work surface lighting as well as effect lighting while enhancing the sense of interior space by creating layers of element from the viewer to the ring to the dome to the ceiling. These layers are articulated by light which can modulate prospect and refuge. |

|

| By Friday, November 3rd, the mediaPOD was almost ready for presentation. The photos below were taken at end of day, Monday being reserved for finishing touches, and setting the stage for the UVA visit and the photo shoot of the mediaPOD to follow. After feedback from UVA and other potential users, the final prototype will be produced employing typical AI woods, finishes and Trade Dress. This MULE was taken further than usual - beyond proof of concept - so that we have a good sense of how to solve the remaining design problems and detail the first production product. Also, the Mule is certainly functional and after it has served its purpose of informing the prototype we will seek to find it a home where it should have many years of useful life. |

|

| A view of the sliding, rotating shelf mechanism which holds the monitors, keyboards and any media equipment. As shown, the shelf is in it “back” resting position. The Armature comes up from the floor, holds the shelves and terminates at the light ring. |

|

|

| A view into the interior with both doors open. The seating bench will have cushions. The slots below the bench are pull out foot rest to fits different size people. In the production version the floor will be carpet for comfort and sound abatement. The light rig at the top provides adjustable lighting. Where required, a sprinkler head will be located in the center of the ring. The raised floor provides venting, heating and wire chases. A turn table option is provided. |

|

|

| Shown closed is one of two doors which swing open to provide entry including wheel chair access. The left side door is not mounted yet. The doors follow the geodesic geometry. They have to achieve ENTRY. |

|

|

| The red connector nodes will not be necessary in the center of the hexagons and pentagons with the prototype and production models as these will be built and shipped and pre assembled units. This change will visually lighten the appearance of the POD inside and out The tinted plexiglas glazing provides good acoustic isolation. |

|

| As MULES go, this is a unusually complete product. It will be possible to go directly to pre-production (shippable prototype) as the next step. This is actually what UVA wants as they are testing a number of alternative solutions prior to building out a larger facility of X-ray viewing/analysis stations. It is our intention to work with other users who will specify with us to prototype other uses for the mediaPOD. One such new user is the Masters Academy which is now getting ready to extend its 6th grade facilities as a “school of the Future” project. [link: mediapod uses]. |

| The AI Team produced this iteration of the mediaPOD, in abut a month, while also continuing the production of a number of other customer projects. After the initial sketches, most of the design details evolved through dialog and the actual cutting of wood. The team: |

| Steve Atkins |

Fabrication of POD base, frame and seating foot rests. |

| Mike Bryne |

Fabrication of POD frame, connector hubs, light ring, shelves, doors. Painting. Procurement of materials. |

| Steve Howard |

Fabrication of connector hubs and Plexiglas glazing inserts. painting. |

| Tom Mack |

Fabrication of frame. |

| Rodney Meadows |

Project supervisor, original geometry and mock up. Fabrication of frame, doors, seat, x_ray boxes, Armature and lighting. |

| Marie Payton |

Painting and plants. |

| Matt Smith |

Fabrication of frame trim, connector hubs and plexiglas glazing inserts. set up lighting for presentation. Installed x-rays. Painting and plants. |

| Patsy Kahoe provided coordination, scheduling, UVA liaison, general office functions and set up POD up for presentation. RK and Suzanne Bruce, financing for the project. The AI Crew brought plants and objects from home, including x-rays, to decorate the POD for its presentation. Robert Beals produced the sketch for the Armature. Jerry Headley, Doug Cantrell and Lisa Piazza, provided research and design feedback. |

|

UVA Radiology Department Visit |

| On November 6th, UVA was presented the mediaPOD MUle and provide us valuable feedback necessary to our completing the interior layout. |

| It was decided to keep the seating bench as it presently is. The movement of the Monitors, toward the users, will have to be greater than we now have and the solution to this was found. The right to left movement of the monitors is fine. The remaining major issue was the adjustable work top for the users. It was decided to put this on a rotating turn table so that it can dock under the monitors, can raise and lower to support stand up work at the monitors, and rotate around 180 degrees to fit over the laps of users when they are sitting on the bench. Two PCs or sets of keyboards and mice with pop up screens will reside on this rotating work top. The work top will also have embedded led task lighting so as not to interfere with viewing the screens. Overhead lighting will be eliminated over the mediaPOD so that exterior lighting does not challenge viewing and cause unwanted reflections. |

|

|

| The seating benches are higher than standard chair height in order to facilitate movement to and from standing and to keep the eye line of the users in the center of the monitors. The slides under the bench provide a variable foot rest for people of different heights. For stand up viewing, the monitor shelf will have to go higher than it is now. It was decide to reshape the Armature to allow this and bring the shelf a bit closer to the seating which will also be place a few inches closer to the center of the POD. This will cut down on the necessary horizontal of Monitor shelf. The shelf will have about a 5 degree tilt forward function so that as it advances toward users who are seated, the eye line-angle is adjusted appropriately. It was also decided to extend the seating bench around to the right (centered on the red node at the potted plant in the picture) - this will allow comfortable seating for five people. |

|

|

| In case ADA requires wheel chair access, the bench section to the left of the entry doors will fold back to make the appropriate space. UVA is checking on the necessity of this. If so, a ramp unit will slide out from under the raised floor at the step shown below. |

|

|

| The air venting system will pull from the base and supply out of the two sides of seating bench. The air will then circulate around the dome and exist from the top pentagon. The equipment will supply a fair amount of heat. each person adds about 100 watts each. Even as we were in the POD for about an hour, with the door closed, we could feel the heat build up. Air turn over will have to be every few minutes. We will vent the large piece of equipment out the back of the POD. The sound abatement was very good and will be better in the production version with tighter doors and thicker plexiglas. A carpet floor will be necessary. The POD interior is acoustically lively without being annoying but will be too reflective without a soft floor. One advantage of this s that occupants do not have to speak loudly to be heard by on another inside. This will reduce the sound coming out of the mediaPOD. Music and sound effects will be spectacular in this environment however we have not tested for this yet. |

|

|

| As always, it is good practice to have the real users to the shop when a new design is being worked out. This is how the tacit knowledge is communicated. As example, it was not until this visit that we understood just how close the screen had to be brought to the users so that precise measurements, right down to pixel scale, can be made. The mediaPOD will be unusually proficient in its ergonomics and adjustability allowing users to do precise work, as a team, without compromising their individual requirements for comfort and health. These adjustments, as it typical of all of our WorkFurniture will require a measure of interaction between the users and the POD - something which we consider to be a positive feature as did the UVA visitors. |

| In terms of the “look” of the mediaPOD UVA would like a more sophisticated, industrial, technology look. For their application I agree with this assessment. The application of our standard materials and detailing will provide a natural migration in this direction. We will provide other materials and details unique to them to render this look into being while preserving the playfulness and warmth of the concept. |

|

Completing the Design Development Process |

| The rotating work top and further extension of the monitor shelf will be incorporated into this version of the MULE. All the other changes necessary for the first prototype can be worked out on paper. The work top will make the MULE more useful for a variety of uses for whatever it future life requires. |

| Beside getting all the details worked out for this one application and moving the MULE to its new home, the major task ahead will be to refine the structure and the build process of the mediaPOD to enhance its quality while reducing unnecessary cost as much as possible. PODs are expensive as the are in effect rooms as well as workstations. If we can get the manufacturing efficient enough the component nature of the mediaPOD will act in our favor and result in our best quality/function/cost equation yet. This will be critical to this becoming a truly successful product. |

|

| This has been a fun prototyping process from the beginning. We have improved our design-team - fabrication-team processes and have experienced a beneficial interaction with UVA, our first user. The mediaPOD meets a number of functions we have been seeking to get built into our PODs for over a decade of making and using them. Above all it is a “fun” product and people seem to be responding in a positive way to its “personality.” I think the mediaPOD will have a long life. |

|

| The shop sent a picture of the frame detail. While remaining the higher frequency of the MULE, this detail provides the sharpness of my original design as well as more glazing area because of the thinner profile. This detail will also provide more of the contemporary-look that many are looking for and I originally intended. |

| With these frames, the hubs - as used on the MULE version - will not be required. The hexagon and pentagon sections will bolt together through the frames themselves. The triangles will be filled with glazing, wood-acoustic panels, screening and shades as the program for a specific application requires. |

|

| Over the last month, there has been extensive dialog back and forth between our design team and the UVA and their architects and engineers. A number of code and other design issues have been discussed. These have been productive session an the mediaPOD is entering it final configuration design for the UVA project. The criteria has been altered somewhat for this first application however. Client approval is expect shortly and fabrication will begin immediately. Click on the graphic above to follow the final design, engineering, fabrication, and install process. |

|

|

| mediaPOD Design-Build Process |

|

|

|

| workPODs - A History of Taylor Design |

|

|

|

| A Future By Design - Not Default |

|

|

|

| A Furture By Design - Worthy Problems |

|

|

|

| Matt’s 5th Domain - Creative Augmentation |

|

|

|

| CyberCon Concept - 1979 - 1983 |

|

|

|

| eSpaces - reinventing the Workplace |

|

|

|

| Faciliatating Complex Emergent Systems |

|

|

|

| The 4 Step Recreation Process |

|

|

|

| Making Place - Tour MGT Environments |

|

|

|

| mediaPOD - Schematic Concept |

|

|

|

| RemotePresence and Remote Collaboration |

|

|

|

| the Solution Box Architecture |

|

|

|

| THERE to HERE - every day, every step |

|

|

Matt

Taylor

Elsewhere

August 20, 2007

SolutionBox

voice of this document:

ENGINEERING • STRATEGY • PRELIMINARY

|

|

click on graphic for explanation of SolutionBox |

posted:

August 20, 2007

revised:

February 16, 2008

• 20070820.870954.mt •

20070908.231655mt •

• 20071103.090911.mt • 20071107.767609.mt •

• 20071113409120.mt • 20080216.566301.mt •

(note:

this document is about 97% finished)

Copyright© 2007, 2008 Matt Taylor

Certain

aspects of the system described are patented and in patent

pending |

|

|