WorkPod

CubeOffice and Armature system

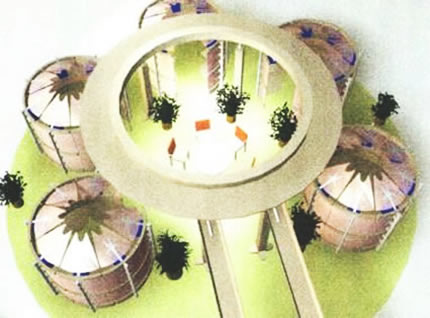

Capital Holding Corporation - 1990 |

refining the navCenter concept |

Virtually

all my architectural work of the 1990s was directed toward

the refinement and actualization of the navCenter

concept and refining the tools and processes by which we design,

build and operate these environments |

| The

floor plan for Capital Holding, drawn in 1990, is

the first layout showing the workPOD™, CubeOffice and Armature™ Systems [link: armature]. Elements of the Armature concept were

incorporated into their navCenter built the following year. As a WorkFurniture system, the CubeOffice was prototyped in 1996, the

workPOD in 1998 and the Armature in 1991, 1997,

1998, 2000 and 2002. With these, we have created an

entire system covering from wall-to-wall, floor-to-ceiling.

An architectural scale, flexible WorkFurniture system that provides easy user controlled adaptability, arrangement and branding options. |

|

| Capital

Holding Center opened in 1991 with built in place

steel Armature system, adjustable WorkWalls, ramps to different floor levels, with multimedia technology and KnowledgeWorker loft area. |

|

| At

the Borgess NavCenter [link: borgess navcenter], the entire 8,000 square feet

was reconfigured (along with sound, video and computer

network) by a small team of Taylor KnowledgeWorkers

in 3 hours. The goal was for end-users to do

this with three simple tools and no “expert”

or “tech” support. As a test of this, in

a 1999 7 Domains Workshop, the participants walked

in to an almost totally deconstructed space. They

were charged with setting it up in two and a half

hours from scratch and to do so in a way that it had never been arranged before. They succeeded. |

|

Captial Holding Radiant Room

1991

|

| First generation POD developed by Paul Lyons installed at the Palo Alto knOwhere Store in 1997. This POD can be configured as a “S” curve with work stations on either side or as a enclosed circle forming an 11 foot “office” space. Wiring runs in a channel at the base so the entire set up can be feed from one source. Each of the sections are built up from a choice of several components and can be moved as a unit then reconnected as an assembly. |

|

|

| The

surprise with the workPOD was that early users did not

know how to use it. Originally, we built twelve and

employed them in various projects. The response was

divided. Half the people loved the Pod and the other

half disliked it intensely (almost everyone liked

the CubeOffice system). This did not surprise us but

what did was that even those who liked the Pod had

difficulty learning how to use it well. |

| Of

course, I have wanted a POD since I first developed

the concept so I took advantage of this situation

to make one at the Palo Alto knOwhere Store my home.

I was, for over three years, a working Guinea

Pig [link: matt’s workspace at knOwhere] for POD use and research. |

| In

recent years the general acceptance of the Pod has

grown. It is very popular now the big issue being

affordability with the Paul Lyon’s version. The

new Blackburn Pod (2002) will cost about half a much. It

also accomplishes our goal of rolling as a single

unit. As it is built from CubeOffice components it

fits well within the entire system and production

schedules. The completion of the Vanderbilt project

in mid 2002 actualizes the vision and intent of the

1990 sketch. A 12

year development process from idea to regular

production. |

|

|

In

2002, Bill Blackburn developed a Pod for

the Vanderbilt

Center for Better health based on the CubeOffice system. This is very

close to my original Pod design which I conceived

for Vanguard in 1995 yet much easier to build and configure in a wide variety of ways. The VBCH navCenter was built and installed, mostly from stock components, in less than 30 days.

Click on the graphic (left) for a history of MG Taylor/AI POD development 1990 to 2010. We have 5 PODs we are building today. It is still a low production business and we still have yet to build out a floor based on of this solution. |

|

|

|

|

| The Cube Office System is based on a two foot by two foot by one foot deep book shelf Module. A double wall provides a three inch space for sliding doors. With in the 2 foot module, a variety of storage unites, closet, pull out secretary unit and work stations are provided. Everything you see can be taken down, moved and reassembled using three tools with no damage to walls, floors or ceilings. |

|

|

CHP

Cube Office System

New York City

1998 |

| The

Cube Office system builds up from a basic 12 by 24

by 24 inch module to complete “office” scale.

The cube components can contain pull down secretaries,

lateral files and storage units. An “office”

can be taken down and erected some place else in a

few hours with out leaving a mark on the existing

built architecture. |

| A

second generation (Foundation II Series) of this system

has been developed and installed in the CGEY Atlanta

ASE environment. |

|

This

version of the CubeOffice, built in 2000, introduces

the Gatling Post which facilitates a greater

use of glass wall which can be configured in

a variety of ways and angles yet easily moved. The Gattling

Post is now a multi-use

component of the system. This application of the system created a an enclosed KnowledgeWorker work area that can be moved anywhere in the space with relative ease. The structure is self supporting and does not depend on the existing building. |

|

|

| The

CubeOffice System can be used to create stand alone

shelving, workstations, storage systems, wall systems

and PODs. It is flexible, moveable and structurally

stable when constructed. It can be maintained and

moved by the end-user eliminating the issues associated

with scheduling and paying for professionals. The

CubeOffice System is

the backbone of the 1990 concept. |

|

POD

installed at Palo Alto KnOwhere Store in 1997

my work enviornmnet 1999 to 2003

|

To

us, the Pod represents the basic amount of

space and amenity that every KnowledgeWorker

requires. Of course, there are several different ways

to accomplish this utility and function. The Pod is

one. The skin of the Pod can be fabric, wood or Plexiglas

- or sections can be open. This facilitates great

flexibility and adaptability. |

| A

second generation (Foundation II Series 2000) of the

Pod has been developed that allows the system to build

up from one work station (a section) , roll in sections

and as a single unit. The new version is made up of

50% fewer parts than the first and actually docks

with our curved WorkWalls. The

Pods can be arranged in clusters

- or in villages as shown on the Capital Holding layout

and indicated below. By using both sides of the Pod

surfaces, high variety layouts can be accomplished

that achieve remarkable density while at the same

time creating spaces of great Prospect and Refuge

and individual utility. |

| The

Tracery elements of the Armature System act as an visual

integrator, ties the villages together, provides chase-ways

for utilities and one means of circulation. It also

contributes to defining vertical scale. The armature

is composed of moving “plug and play” components

that the users can reconfigure themselves. |

|

ArmatureSystem

- 1999

Showing Foundation II components |

The

Cube, Pod and ArmatureSystems are components that

compose the layout indicated in the 1990

sketch. The layout, itself, can be accomplished

in a variety of ways and adjusted, from time to time,

as required. “Smart” furniture can “know”

certain rules of arrangement and “recommend”

layouts based on Pattern Language values, prior successful

solutions and codes. Great density and utilization

can be accomplished along with a human focussed life-workstyle

- all from affordable, low volume manufactured components.

The technology, means and methods that facilitate

this are part of our Patent and Patent Pending and other IP. |

| The

aramture approach was further developed with the (unbuilt)

Vanguard Development Center in 1995. |

|

Vanguard

Neighborhood Layout - 1995 |

The

metaphor of streets, Alleys, neighborhoods, and so

forth, creates a powerful specification in regards

traffic flow and amenity. The strong architectural

forms of the basic elements and armature allow a variety

of different specific furniture solution-set clusters

and “negative” spaces that make the niches

for sitting areas, support tools, one-off workstations

and small team work areas. Larger group areas are

defined by Cube Office components and fold-out WorkWall

systems in a variety of configurations. Prospect and

refuge along with great variety and flexibility can

be achieved on the horizontal plane. However, this

is not enough. The constant flat, low ceiling - particularly

in large spaces - is not nature to human consciousness.

There is a different psychological sense in looking

up and downward within an architectural space. This

“sense” is important to certain mental states

and, thus, to certain processes.

|

| For

years we have encourged clients to develop the vertical

space of their environments. There are many reasons [link: vertical space] to do this. There are, also, several obstacles to

it: codes, the limits of existing building structures,

the perception that this costs more - the overwhelming

paradigm of 8 to 10 feet ceilings as the “norm.”

We accomplished significant vertical movement with

the Orlando Management Center - 1985 (ceiling changes

and floor platforms), AEDC - 1992 (ceiling changes

and floor platforms) and the Palo Alto KnOwhere Store

- 1997 (ceiling changes, second floor balconies and

skylights). However, the most comprehensive use of

vertical space was the 11,000 square foot Capital

Holding project - 1992 (second level KnowledgeWorker

and tecnology work-deck). Note: this was surpassed in 2007 with the Unicredit project in Turin, Itally [link: unicredit tour]. |

|

|

Orlando

Management Center built 1985 |

This

Center was in continuous use for 14 years. It

has served three different “owners,” the

Acacia Group, MG Taylor and, now, CNL. The flexibility

and adaptability built-in to its layout has allowed

it to accomplish three divergent missions without

requiring modification. While capital intensive when

first built, its durability and adaptive utility has

netted a life cycle cost lower than conventional construction.

|

Most

of the 6,000 square feet is open and adaptable - four

large areas flow into one another or each can be closed

individually or all at once. The three level ceiling

and light coves accomplish three things: small areas

are defined as part of the larger space (so that “place”

is maintained with 6 or 60 in the space); the ceiling

is free of the usual clutter and therefore “reads”

as an active architectural element; and, the HVAC

is delivered from within the coves and does not blow

on people in the space. |

|

|

| AEDC

Gossic Leadership Center built 1992. Jerry Headly, Design Development and Architect

of Record. This was without question the most productive navCenter ever built in terms of organizational transformation and economic results. |

|

| This

environment was built for the Air Force provided

over 100 DesignShops for the Air Force, NASA, the Aerospace

community, Universities, local businesses and other

members of AEDC’s ValueWeb within the first 30 months of operation. The balcony above the

Radian Room is the KnowledgeWorker work-loft. |

|

Palo

Alto KnOwhere Store built 1997 viewed from the second

level incubation Loft. The knOwhere Stores incorporated retailing, event environments , business incubation, research and the MG Taylor corporate offices. They operated between 1996 and 2003.

Work

under way at the two story high opening dome at the Palo Alto

knOwhere Store center point. The entire front wall of the PA store opened up and so did the dome. This provide natural ventilation which reduced the need for heating and cooling in the temperate Northern California environment even in the center of a city. |

|

|

|

| These

views clearly illustrate the power of vertical spaces.

This kind of vantage point cannot be accomplished any

other way. Sadly, it is too often missing in contemporary

architecture. Note the technology

armature over the Radiant Room. It allows for a

variety of setups and the space can be set to comfortably

accommodate 10 to a 100 people. |

The

dome cost $20,000 and was considered a great expense

at the time. This will be about 100 dollars a month

over the period of the lease. This simple “trick”

of curved forms, low, medium and high ceilings, with

the play of natural light - all interacting with appropriate

dynamic rhythm - creates a space that draws people

like a magnet. This area acts as the “center”

of the 20,000 square foot space and turns what otherwise

would have been a low, dark environment into a dynamic,

exciting place to be. The dome with the first and

second floor ceiling collars added less than one-half

a percent to the cost of the project - netting a high

architectural return on investment. |

|

|

| View

from the knOwhere balcony under the dome to the first floor area. These spaces, on both levels, became the most popular in the environment and most spontaneous in their use. Even thought this was the most public place in the 20,000 square foot building, it was the first place people chose to do their intimate team work. |

|

Budgets

come and go - buildings last a long time. This building

is forever altered and now has a value many times

the investment. Spending money on “features”

will not necessarily do this. The treatment has to

be based on intrinsic human values and the way that

people interact with space. It has to support the

processes that take place within the environment. |

In

a world that increasingly builds bland environments

lacking identity, brand and “sense of place,”

people respond strongly and positively to strong architectural

armatures, the use of natural light, fresh air as

the weather allows (more often that supposed) and

carefully selected high quality materials. This does

not have to be expensive. The Palo Alto lease, including

lease hold improvements and interior furnishings, was

under $30 a square foot per year in a real estate

market that had less than 1% vacancy at the time

of remodeling, and typically rented undeveloped, unfurnished

space for more than this. |

| The Capital Holding project also involved

extensive level changes. Built on the first floor of

a traditional building a two story space was created

by going down five feet, opening the ceiling to the

second floor concrete slab and building a loft in-between. |

|

| Capital

Holding navCenter built in 1992. The view is

from the 12 foot wide by 80 foot long KnowledgeWorker Loft area, looking down into several work rooms and two Radiant Rooms. |

|

|

| This

created a variety of different spaces in what otherwise

would have been a uniformly dull environment. The

schema actually build a “building” within

a building and allowed a progression of incremental

environs as users moved in and down from the traditional

areas surrounding it. While built in a corporate headquarters,

and while being sensitive to the traditional detailing

and materials (which were brought into the space),

the navCenter “felt” like an off

site experience and a world of it’s own. |

The

Capital Holding steel structure created an armature

which acted as a conduit for electrical, LAN, multimedia

and phone lines - and, supported the the KnowledgeWorkers

deck from which the above photo was taken. The WorkWalls

could be moved from one side to another - along with

all lines - allowing the Break Out/Office space to

open to another area of the Center. It was with the

Orlando Management Center and this project that we

laid the foundations for our technology and wiring

strategies. |

| Throughout

the 90’s, considerable technology integration

was accomplished. Video, audio, computer, phone, LAN

lines were developed into an adaptable “plug

and play” system allowing multimedia capture,

production and playback to become a real-time, integral

part of the work process. |

| The

Borgess NavCenter has Foundation 2 WorkWalls and Cubes

with detachable, rolling “power poles” that

“plug and play” with the wiring above, In

July (1999) just a few weeks after installation, the

KnowledgeWorker staff reconfigured the entire 8,000

square feet space - including A/V, power and LAN lines

- in 3 hours. |

|

The

Borgess insall - May 1999

|

The

next stage of this [link: technology

integration] process involves building computer

and multimedia technology into the WorkFurniture,

establishing Center-to-Center RemoteCollaboration and RemotePresense, and developing the first generation

of “smarts” into the system components themselves.

This work is presently very high on AI’s agenda

and is key to several aspects of our Patent and Patents

Pending.

Most

of the basic ideas that were put into product

during the 90s came from my 60s, 70s, and 80s thinking. We built more, however, in this last decade

than all the others before it. This allowed us a faster,

more iterative, rapid prototyping process. The 2001

and 2002 installations became mature expressions of

these ideas.

Even so, in the 1990s, we are just getting

to the level of component design and manufacture that

we envisioned when we started. |

|

|

|

|

|

| The

2002 Vanderbilt project moved further along the

technology integration path by employing plug-and-play

power poles, which connect to a number of bundled wire whips in the ceiling, and rolling monitor stands based on

the Gatling Post system. This way a large foot print can be arranged in many different ways and equipment connected quickly without extensive rewiring. The floor is left completely free of plugs which interfere with rolling WorkWalls and furniture. |

|

The

level of component capability, that we are able to

deliver today, allows a utilization of space

and level of knowledge “manufacture” than

can not be achieved without it. We are now able to produce an environment

that utilizes Pattern Language principles, serves

the full venue of individual, team and large group

collaboration functions, provides greater personal

space to each KnowledgeWorker than other systems, and overall, achieves greater space utilization

than standard layouts using existing manufactured

components.This

is not an accident but the result of a decade of progressive

projects that integrated design and building with operations. All

this can now be done at competitive costs and in a

radically reduced design-to-move-in time frame. This

cannot be accomplished by design - or even manufacturing

- alone. While there are issues related to the design of architecture - this is not the major problem. The

furniture manufactures are capable of far more progressive

designs than the present market will buy. Clients

and customers want more but maintain a buying-system

that makes the creation of quality workspaces almost

impossible. The total system and method by

which this work is done is the “problem”

- I discovered this upon my entry [link: 1956] into architecture. I have devoted most of my years

of work since then to discovering - and inventing - a way that consistently produces another kind of

result. |

|

|

AI

PODcluster - ArmatureSystem - 1999 |

Getting

to this “point of beginning” took 20

plus years since what is now MG Taylor was formed.

Every step along the way was funded by a real client

solving a real problem. Every piece and component

went into a work environment dedicated in some way

to creativity/collaboration augmentation. The design team that did this

work has been small. I started the process alone and

was joined by Langdon Morris in the late 70s and again

in the early 90s, and then the current members: Bill

Blackburn in the early 80s and who operated AI

[link: ai] 1992 to 2002 and still designs for us, Gunner Kaersvang (1995-1999),

Paul Lyons 1997- 2002). On the design-detailing

and production end, Bryan Ross since 1987 becoming

full-time manager of the AI production facility

starting, 1998 to 2005. As

small as AI is, it has one of the most comprehensive,

and integrated, lines of work furniture solutions

and design services on the market today. And,

it sells more of this new kind of furniture

than many of the large manufactures. As we proceed

along this path, we will build an integrated design/build/deploy-use

supply chain that is deeply embedded in our larger enterprise [link: mgt valueweb]. |

| When we started MG Taylor there were no components that did what we needed - not on the utility

level nor on the aesthetic level. More importantly,

however, was our need to accomplish - through direct experience - the close connection between design-build-use [link: dbu model].

This is necessary for getting complex product design

and intimate market fit. Because of our ability to

integrate “lust-to-dust” we have been able

to field solutions that multi-billion dollar organizations

have failed to match. Lean production is useful, but it is Lean design/build that is necessary for true innovation. We have not

been able, yet, to do this at any great scale. To

do this we will have to partner with many new, large

and small, ValueWeb [link: valueweb model] members that have capabilities and core-competencies

that we do not. This, however, is consistent with

the Network Economy concept and our own organizational strategy. |

We

are just beginning to see - in this newly emerging

postindustrial, global economy - this kind of linkage

in ValueWebs [link: valueweb architecture] and supply chains. Product improvement is both user-driven and “pushed” by a strong producer

vision. Batch production is giving way to lean,

mass-customization methods allowing for rapid development

and evolution of products and services. The distinction

between products and services is blurring. Design

wins as we can see with the i-Mac, TT and Mini. Making

things and delivering them to a market is the best

way to design. This is employing the 4

Step Recreation Model [link: 4 step] and 3

Cat [link: 3 cat] Models as an OS for a complex ValueWeb.

It involves, for us, using our product/service offerings

as the factory for making them. We are intimately

involved in the entire design,

build use cycle. |

My

design work of the 90s was not just about the “what”

- the product. It was about putting in place an “engine”

of creation that could build the environments we wanted

- which themselves, were “engines of creation.”

This was, and still is, a bootstrap process. Multiple

iterations to make the tool to refine the tool to

make the tool. The

decade of the 90s has come and gone. The work we now

have in progress will accomplish many of the elements

indicated in the Capital Holding sketch. [link: ch sketch] I do not see this work as the “end” - I

see it as a minimum foundation for an effective future

work environment. In reality, we are just getting

in place many elements that should have been ubiquitous in the work environment long ago [link: reworking the workplace]. |

|

Joseki

Offices, June 2002, were hand built on site by a team of students from SFIA. A mundane space was turned into a flexible environmnet expressive of the Joseki brand.

[link: future link] |

|

|

When

a new position is created, it acts as a meme [link: what is meme].

This “sets” the game, within which, all

the variations are played out until a new game is

created. The “office” - the workplace -

is in the process of being recreated. Which concept

of “office” gets on the “increasing

returns” slope involves a critical competition.

A competition of ideas, of mental bandwidth of decisional

maker’s attention. It is not the money issue

that matters so much as the total set of consequences

that flows from the choices made and what is consequently

built. How people think and work frames the range

of solutions that they can see and work on. This in

turn establishes the quality of what

we do as a

species [link: a future by design not default]. |

|

Matt

Taylor

Palo Alto

February 20, 1999

SolutionBox

voice of this document:

BUILD • TACTICS • EVALUATE

|

click on graphic for explanation of SolutionBox |

posted:

February 21, 1999

revised:

October 15, 2010

• 20000603.905342.mt • 20001101.768821.mt •

• 20010204.569812.mt • 20020612.640091.mt •

•

20020617.666622.mt

• 20020619.123400.mt •

• 20101015.211209.mt •

(note:

this document is about 98% finished)

Aspects

of the system and method described are Patented and Patent

Pending.

Copyright©

Matt Taylor 1999, 2000, 2001, 2010 , 2002 |

|

|